SaaS service cloud platform for pump equipment

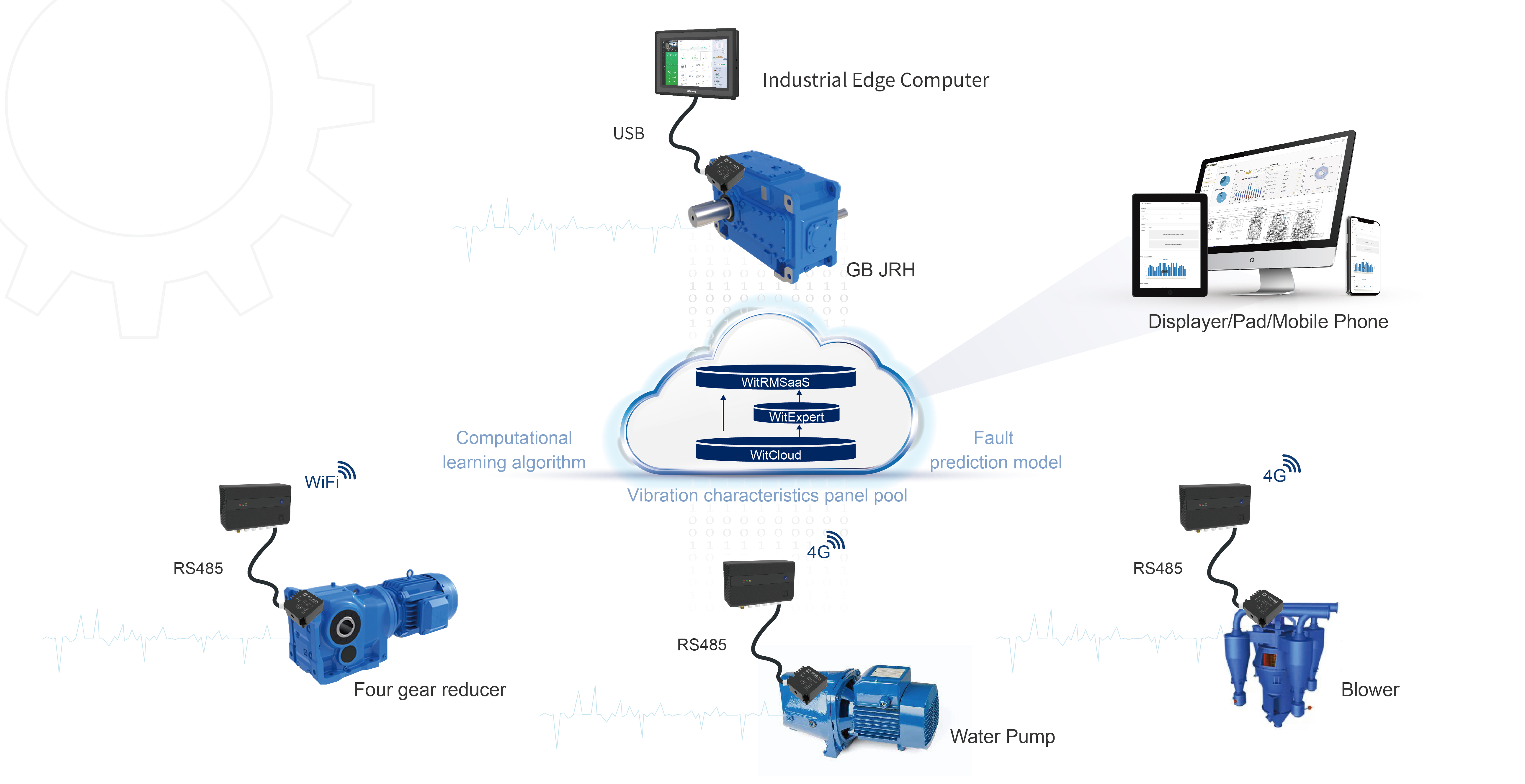

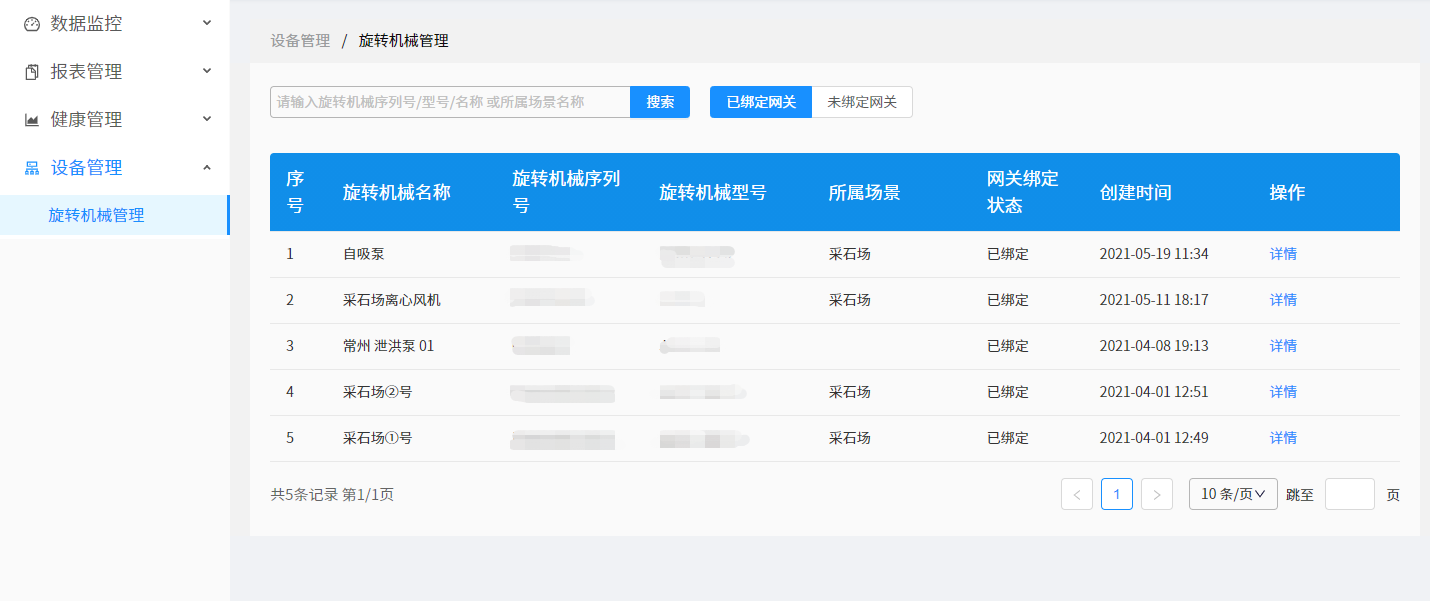

The SaaS service cloud platform for pump fault prediction provides users with platform functions such as status monitoring, fault analysis, scene monitoring, fault management, operation and maintenance management, equipment management, customer management and authority management, as well as platform data reading interface function. Through big data analysis tools, SaaS business cloud platform provides professional users with equipment operation status analysis, early warning fault analysis, and forms professional industrial equipment health diagnosis reports and maintenance suggestions.

Fault prediction algorithm model: firstly, the system collects the vibration characteristics and load temperature characteristics of pump equipment through high-frequency vibration sensor and platinum resistance of Internet of things, and forms a vibration characteristic sample library; Then the intelligent algorithm (machine learning algorithm library) is used to carry out machine self-learning on these original data samples, generate the corresponding fault prediction algorithm model, and form the fault prediction algorithm model library; The fault prediction algorithm model is used to analyze and process the real-time collected data to realize the fault prediction and diagnosis of pump equipment, such as imbalance, misalignment, bearing fault, cavitation, impeller imbalance, looseness, gear wear and so on.

Witcloud

Witcloud

IOT Sensor

IOT Sensor

IOT Gateway

IOT Gateway

PHM System

PHM System

Reducer equipment

Reducer equipment

Air compressor equipment

Air compressor equipment

Blower equipment

Blower equipment

Machine tool equipment

Machine tool equipment

Pump equipment

Pump equipment

Witium trend

Witium trend

Industry information

Industry information

Company introduction

Company introduction

Patent qualification

Patent qualification

Recruitment

Recruitment

Contact

Contact

Online message

Online message

Police record number: 31011202009248

Police record number: 31011202009248