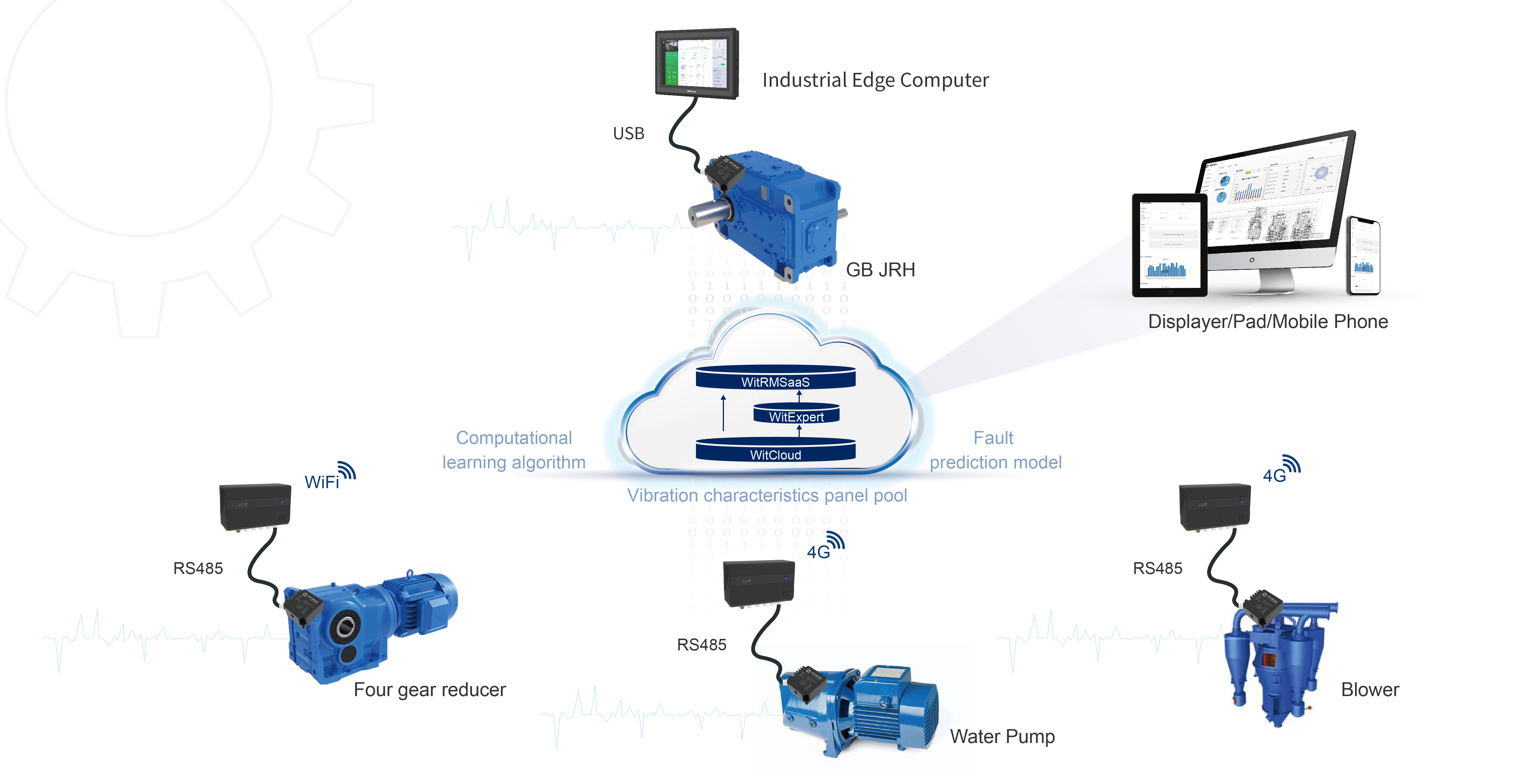

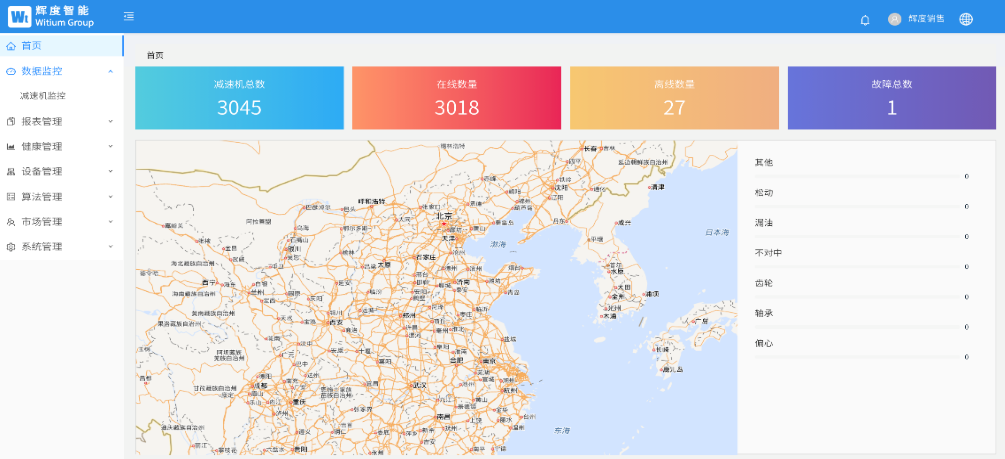

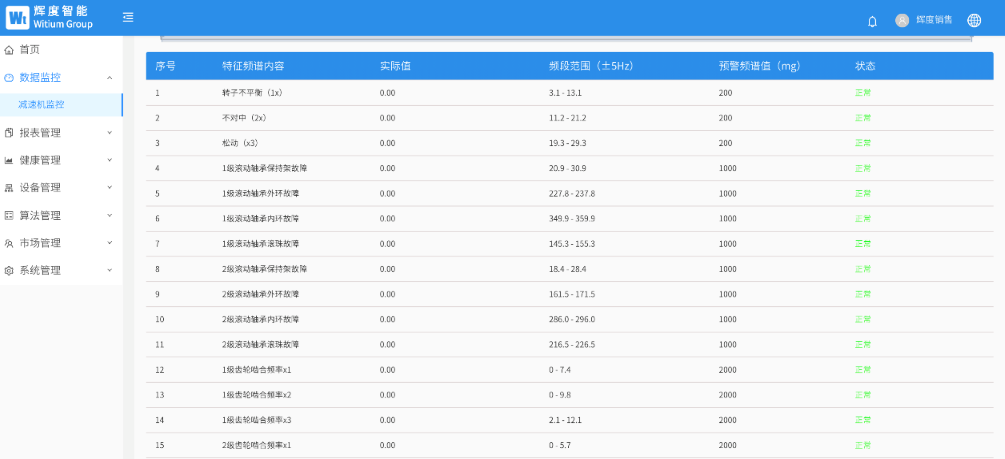

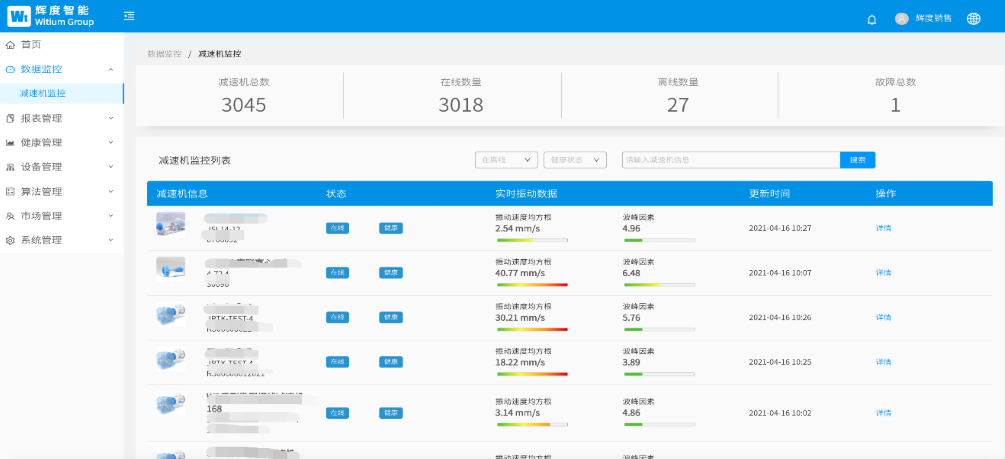

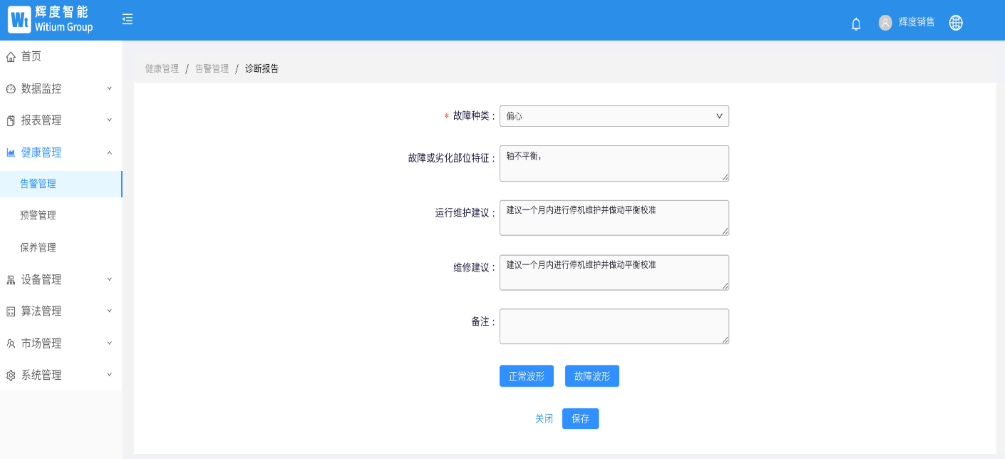

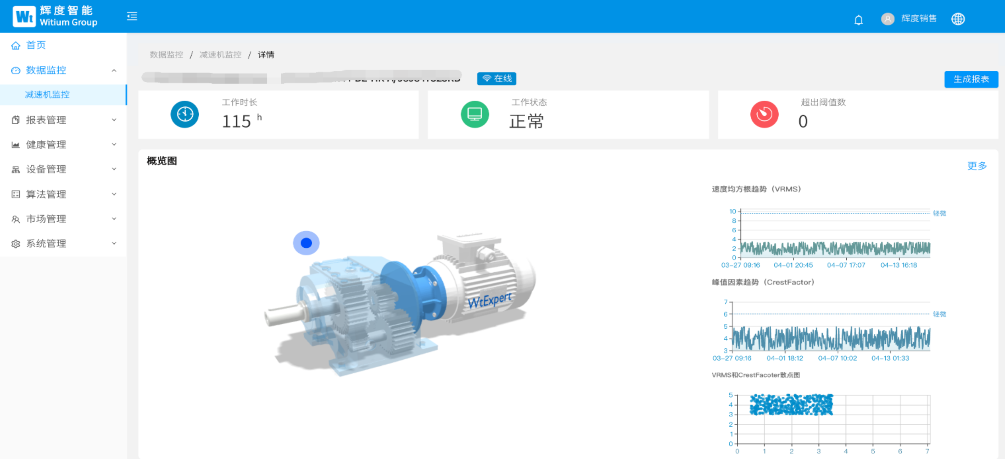

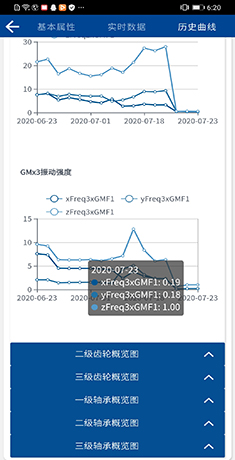

The functions of witcloud cloud platform include: access configuration of vibration sensor and edge computing gateway on reducer equipment (including subject configuration and channel configuration), remote information configuration and equipment firmware upgrade, multiple alarm modes, diary operation and maintenance management, Cloud Architecture on multi-layer edge computing gateway, database backup and retrieval, and management and control of influxdb database.

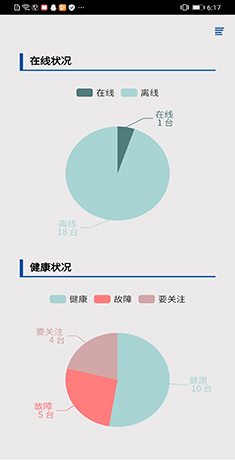

The powerful system architecture of the witcloud cloud platform has scalability, the ability to access a large number of devices and the million level concurrency ability. It can easily access more than 1 million reducer devices and support the access ability of more than 100000 reducer devices each year.

Witcloud

Witcloud

IOT Sensor

IOT Sensor

IOT Gateway

IOT Gateway

PHM System

PHM System

Reducer equipment

Reducer equipment

Air compressor equipment

Air compressor equipment

Blower equipment

Blower equipment

Machine tool equipment

Machine tool equipment

Pump equipment

Pump equipment

Witium trend

Witium trend

Industry information

Industry information

Company introduction

Company introduction

Patent qualification

Patent qualification

Recruitment

Recruitment

Contact

Contact

Online message

Online message

Police record number: 31011202009248

Police record number: 31011202009248